Machines revision

We provide you with the technical expertise of our various services to upgrade and revalue your legacy escomatic machines. A review by “ESCO“ the original manufacturer, will ensures a perfect realization of quality. You send us your machine to revise and in 12 to 16 weeks, we return it to you completely renovated and modernized, with our guarantee.

Possible revision options:

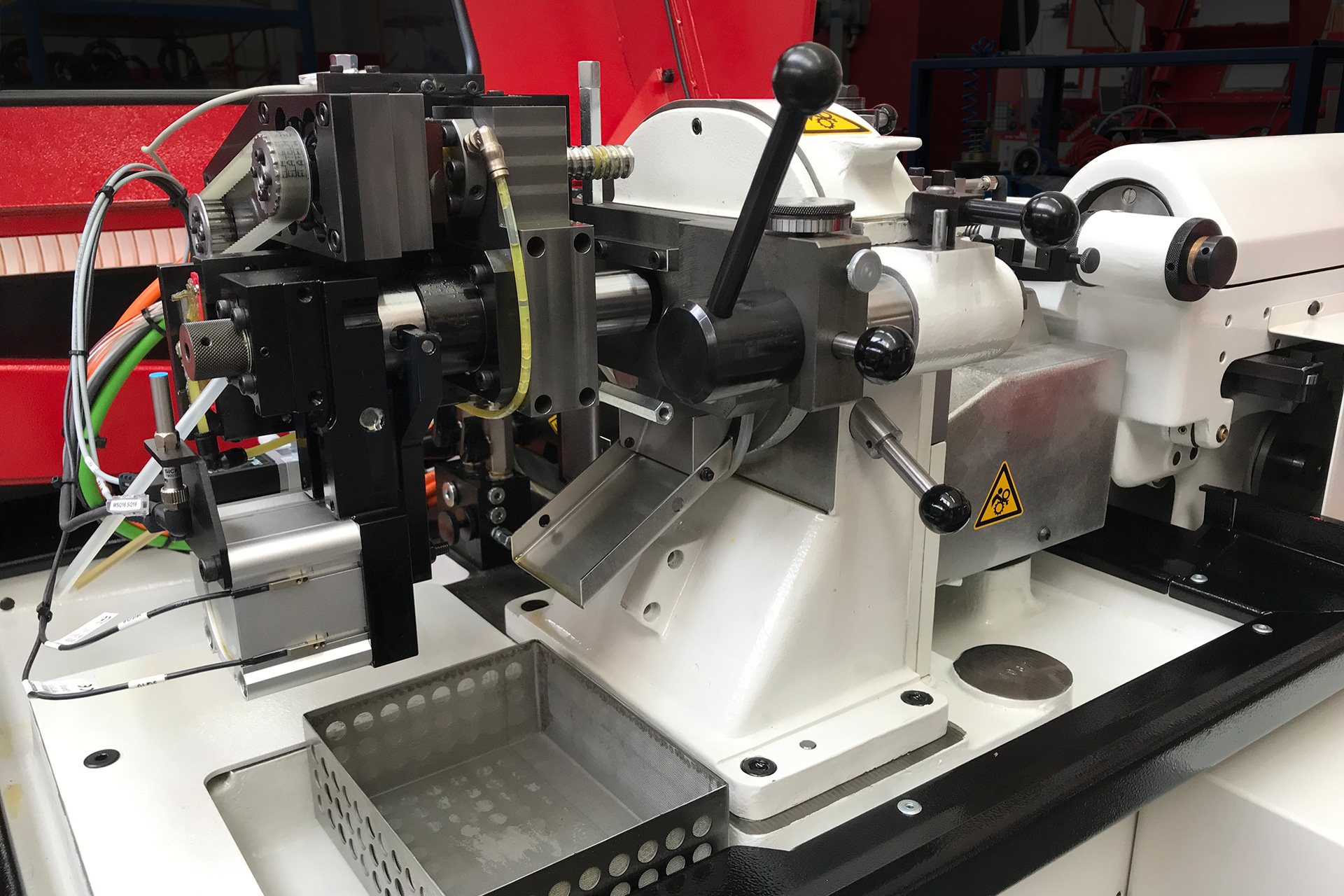

escomatic D2 CNC-UP, an exclusivity

Dismantling all parts, complete cleaning, Revision of all mechanical elements:

– Straightener

– Feed

– Headstock

– Counter collet

Complete replacement of the electric cabinet, Removal of the gearbox and installation of the CNC management system, Tool head revision and adaptation to CNC (remains at 8’000 RPM), New paint (option).

escomatic D2 FLEX-UP

Dismantling all parts, complete cleaning, Revision of all mechanical elements:

– Straightener

– Feed

– Headstock

– Counter collet

Complete replacement of the electric cabinet, Change of the gearbox and adapting to Flexspeed control, Tool head revision, New paint (option).

Equipments and tools

Tooling services, a division of esco group

Are you looking for a supplier who can deliver all your Escomatic tooling requrements without having to contact several companies? Our division Tooling Services, on the basis of your order, will take care to supply to you, all the components of your tooling and will deliver them to you ready for use.

Your advantage: A single order, a single contact, of your complete tooling package at a specific date, and satisfaction guarantee.

Tooling Services range

Standard or profiled Counter Collets

Standard turning and form tools

Cam calculculation, Cam sets

Feed and fixed collets

Standard or profiled feed rolls

Test of equipments