Schweizer Werkzeugmaschinenhersteller

Neben dem Drehen als Hauptprozess bieten escomatic Drehmaschinen mehrere andere Bearbeitungspositionen für die Herstellung von mittleren und großen Serien von Teilen, die hohe Präzision und einwandfreie Qualität erfordern. Von den einfachsten bis zu den komplexesten Teilen garantieren escomatic-Maschinen eine Lösung für maximale Produktivität auf kleinstem Raum.

Unser einzigartiges Konzept

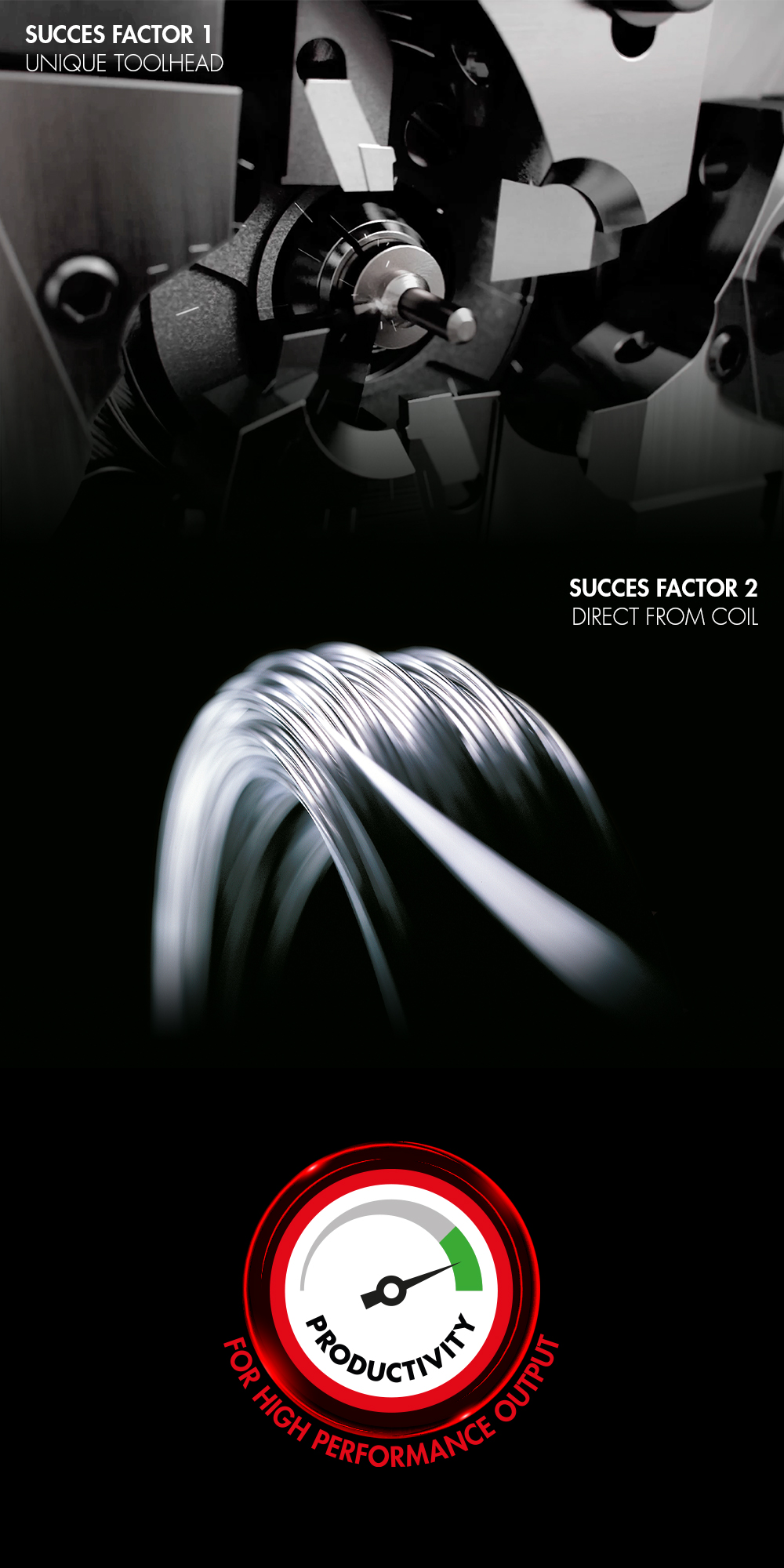

„Stehendes Material – Rotierende Werkzeuge“

Gegenüber konventionellen Drehautomaten zeichnet sich eine escomatic durch ihr individuelles Funktionsprinzip aus. Das stillstehende Material wird als Ring- oder Stangenmaterial zugeführt und mittels eines rotierenden Werkzeugkopfes bearbeitet. Die Nähe der Werkzeuge zum Werkstück bietet unvergleichliche Vorteile bezüglich Stückleistung und Oberflächenqualität.

Das leistungsstarke escomatic-Prinzip ermöglicht unübertroffene Produktivität bei geringen Kosten.

Warum eine escomatic Maschine?

Produktivität

Höchste Produktivität im kleinen Durchmesserbereich

Autonomie

24h Betrieb mit minimalem Personalaufwand

Wirtschaftlichkeit

Kleinste Service- und Unterhaltsaufwände

Terminkalender Messen

MD&M

Anaheim (USA)

SIMODEC

02-06.03 2026

La Roche-sur-Foron (FR)

STOM-TOOL

24-27.03.2026

Kielce (PL)

SIAMS

Moutier (CH)

Pune Machine Tool

04-08.06.2026

Pune (IN)

Swiss Medtech

10.06.2026

Bern (CH)

IMTS

14-19.09.2026

Chicago (USA)

AMB

15-19.09.2026

Stuttgart (DE)

MAKTEK Eurasia

28.09-03.10.2026

Istambul (TR)

mICRONORA

29.09-02.10.2026

Besançon (FR)

MSV

06-09.10.2026

Brno (CZ)

JIMTOF

26-31.10.2026

Tokyo (JP)

Neueste Nachrichten

Entdecken Sie unseren neuen Generalkatalog

Übersicht Maschinen und Applikationen

Innovations ESCO 2020/21 — INNOESCO #8